| General Specifications | |

|---|---|

| Spec: | Description: |

| Operating Parameters | For clean liquids in full pipes with less than 2% solids or gas bubbles |

| Programming | Built-in, 5-button keypad with English, French, and Spanish menu language selection |

| Electronics Enclosure | NEMA4X (IP 66) polycarbonate with clear, shatterproof cover |

| Flow Velocity Range | ±0.02 m/s to 12.2 m/s (±0.07 ft/s to 40 ft/s) |

| Accuracy | ±1% of reading from 0.46 m/s to 12.2 m/s (1.5 ft/s to 40 ft/s); ±0.0046 m/s (±0.015 ft/s) for velocities below 0.46 m/s (1.5 ft/s) Repeatability & Linearity: ±0.25% |

| Display | White, backlit matrix – displays 5-digit flow rate with floating decimal, 14-digit totalizer, relay status, operating mode, and calibration menu |

| Power Input | 100-240 V AC 50/60 Hz, 10 VA maximum Optional: 9-32 V DC, 10 W maximum |

| Analog Output | Isolated 4-20mA, 0-5 V, 1 kΩ load maximum |

| Control Relays | 2 Relays, form ‘C’ dry contacts rated 5 A SPDT; programmable flow alarm and/or flow proportional pulse Optional: 4 additional (6 total), rated 5 A SPDT |

| Data Logger | Built-in 128 MB data logger with a USB output and Windows software. Capacity for approximately 26 million data points |

| Operating Temperature (Electronics) | -20 °C to 60 °C (-5 °F to 140 °F) |

| Approximate Shipping Weight | 5.5 kg (12 lbs) |

| Sensor Specifications | |

|---|---|

| Spec name: | Description: |

| Pipe Diameter (Recommended) | SE16A: 15 mm to 40 mm (0.5 in to 1.5 in) SE16B: 50 mm to 250 mm (2 in to 10 in) SE16C: 300 mm to 1,200 mm (12 in to 48 in) |

| Pipe Diameter (Suitable For) | SE16A: 15 mm to 150 mm (0.5 in to 6 in) SE16B: 50 mm to 1,200 mm (2 in to 48 in) SE16C: 100 mm to 1,200 mm (4 in to 48 in) |

| Pipe Materials | Any metal or plastic sonic conducting material including carbon steel, stainless steel, ductile iron, concrete-lined ductile iron, cast iron, PVC, HDPE, PVDF, fiberglass, copper, brass, aluminum, and pipes with bonded liners including epoxy, rubber, and Teflon |

| Operating Frequency | SE16A: 2.56 MHz SE16B: 1.28 MHz SE16C: 640 kHz |

| Operating Temperature | -40 °C to 150 °C (-40 °F to 300 °F) |

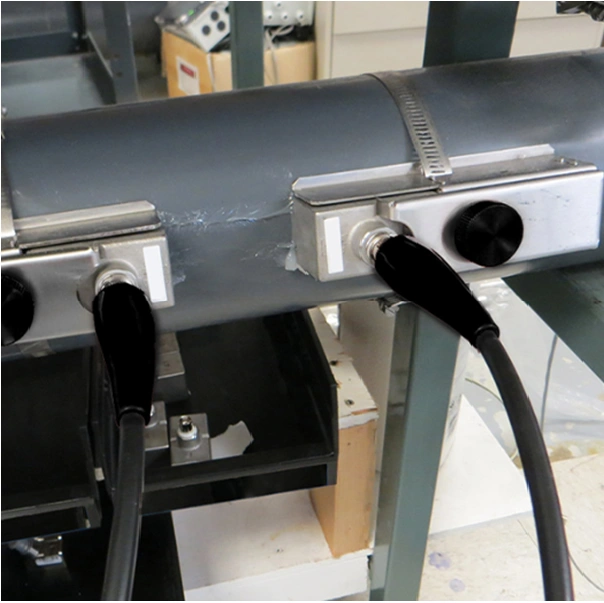

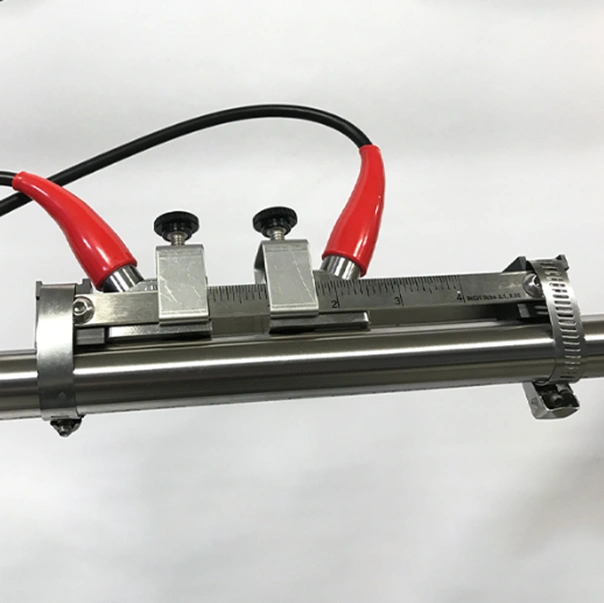

| Transducer Mounting Kit | SE16A: Includes stainless steel track with pipe clamps, built-in ruler, and coupling tape SE16B: Includes a set of stainless steel transducer brackets, clamps, alignment bar, and coupling tape SE16C: Includes set of stainless steel transducer brackets, clamps, alignment bar with a built-in ruler, and coupling tape |

| Transducer Cables | Triaxial, 7.6 m (25 ft) with BNC connectors and seal jackets; extendable up to 152.4 m (500 ft) |

| Hazardous Locations | Certified Non-incendive for Class I, Div 2, Groups A, B, C, D Optional: Certified Intrinsically safe for Class I, Div 1, Groups C, D; Class II, Groups E, F, G; Class III; Encl. Type 4 Optional: Certified Intrinsically safe for sensor mounting in ATEX.IECEx Zone 0, Ex ia IIB T4 Ga, hazardous location |